Construction Nails – How to Choose the Right One

Secure fastening involves the use of the right nail, screw or hinge. There’s a proper fastener to use for any fastening job.

There are a number of nails, hinges and screws on the market. Many have a specific use. This chapter is a guide to help you find the proper fastener for your job.

Nails

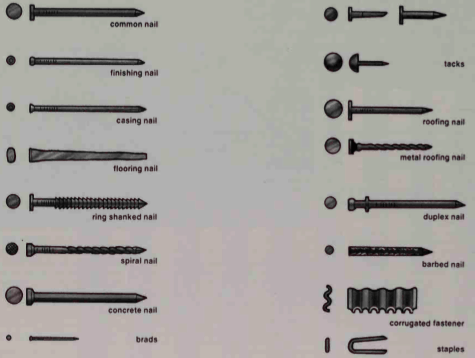

Nails, the original wood fasteners, have developed a remarkable number of specialized uses over the years. There’s a nail type for almost any nailing task.

One nail won’t necessarily handle the job of another, so you need to be aware of the different varieties and their uses, along with a few nailing techniques, to be able to make a secure and durable fastening.

The common nail is the one we’re most familiar with. It’s a heavy-duty nail used for rough framing and general construction work. This nail has a large flat head that won’t pull through the work once stresses are set up on fastened work. The diamondshaped point makes starting easier, and grooves under the head of the nail offer a bit more holding power.

The box nail is similar to the common nail but is a thinner gauge, making it useful for light work or for use where the heavier common nail might split the wood. These nails also have a grooved shank near the head for better holding strength.

The heads of these two nails are large and very visible once driven home. If you need nailing strength in areas such as trim or cabinetwork but don’t want to see the nail head, a finishing nail is used. These nails have a diamond-shaped point at the end and a grooved shank under the head similar to the common and box nails, but the actual head of the nail is smaller than that of the common nail and can be sunk into the wood with a nailset and covered with a wood filler.

Although finishing nails can be used on trim, casing nails are available for these moldings as well. The casing nail is similar to the finishing nail but has a heavier shank for better holding power, and is usually driven flush to the surface and painted over.

In some cases when you’re applying molding, the thin trim won’t need the strength of a finishing nail. A common brad can be used for light-duty holding where no stress is involved. Brads are available in lengths up to 3.8cm (1 1/2in). The only difference between the longest size and a finishing nail is the thin gauge of the brad. When nailing smaller brads, it is sometimes useful to push the brad through a thin piece of cardboard for holding while you drive the brad through the wood. This keeps your fingers out of the way of the hammer and provides for easier, straighter driving.

The roofing nail belongs to this same family of nails where the shanks have grooves under the nail head. This type has a large flat head to resist pull-through and is used to hold composition boards, shingles and roll roofing. The nail is usually galvanized to prevent rusting. They come in lengths up to 5cm (2in) and usually have a heavy shank. The heavier shank limits their use to roofing, since nailing into thin lumber with a roofing nail will cause the wood to split.

The above nails all feature round, smooth shanks. By notching or threading a shank, the holding power of the nail is greatly increased. An example is the drywall nail. The rings on the shank offer greater protection against popped nails or loosened drywall, a common complaint in homes with gypsum-board walls.

Framing, roofing, siding and flooring nails are all available with ringed or threaded shanks. Although threaded nails are more expensive than conventional nails, you tend to get more nails to the pound.

Threaded nails are available with spiral threaded or ringed shanks, or a combination of both. The most common is the shank with spiral threads. The thread is run at a deep angle down the shank, rather than a tightly wound thread as you would find on a screw. As the nail is driven by the hammer, the nail forms a spiral groove in the wood, capturing the wood fibres and retaining them along the shank. This prevents nail pull-out caused by stress on the wood. This type of nail is most commonly used for flooring nails to provide a ‘squeakless’ floor.

The second type is the ringed nail. This type doesn’t twist into the wood as it’s driven but rather goes straight in. The wood fibres then grip into the grooves created by the rings. These nails are also good for subfloor installations.

The third type combines the spiral and the ring to form a nail that’s similar in appearance to a wood screw. These nails have a tight thread, and twist while being driven.

All these nails are difficult to remove once hammering has started, so don’t use them for temporary tacking.

There is a nail on the market spec ally made for temporary tacking, when you need a tight fit between the pieces of wood being joined. This nail, called a duplex head, has two heads, one at the top of the nail ana one slightly lower. The nail is driven until the lower head fits flush to the wood, creating a tight join. The upper head is left protruding for later nail removal.

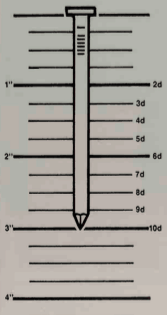

Nail sizes are designated in inches and sometimes through the use of the term ‘penny’. The penny size is denoted by the letter D and was originally used as the price per hundred nails. The term now is used to signify length. The longer the nail, the higher the penny rating.

PENNY GAUGE

A penny gauge is a way of determining a nail’s size. The rating originally denoted the price per hundred. It is now sometimes used to determine the length of a nail. A 6d nail for example is a 2in nail. Common nail sizes range from 2d to 60d. As length increases, so does the diameter.