Contents

Working with Concrete

Knowing how to handle concrete will ensure a long life for your concrete driveway, sidewalk or patio.

Concrete is a mixture of Portland cement, sand, gravel and water, mixed in measured proportions to form a durable and fairly inexpensive building material. Portland cement is a fine powder which, when mixed with water, forms a cement paste that binds the gravel and sand (aggregates) together to form concrete. The aggregates form about 75 percent of the concrete, and the ratio of the aggregates used in the mixture determines the strength of the concrete.

The fine aggregate (sand) must be clean and free of clay or vegetable matter, which will prevent the cement paste from bonding the aggregates. To test for clean sand, place an inch or two of your sand in a jar and fill it with water. Shake the contents and let the jar sit overnight. If the silt at the top of the jar is more than 3mm (1/8in) thick, the sand is not clean enough to use; it will need to be washed. Sand used for mortar is too fine for concrete work.

The coarse aggregate (gravel or stone) should be 6 to 37mm (1/4 to 1 1/2in) thick and must be clean.

The fine aggregate fills the spaces around the coarse aggregate for a tight bond.

Mixing concrete

You can buy ready-mixed concrete or you can buy the aggregates and cement to mix your own. In either case, the addition of the right amount of water is essential to ensure the durability and strength of the concrete. Too much water will make the concrete weak and porous; too little will make the concrete too stiff to work.

Air-entrained concrete is only available as a ready mix. This concrete contains millions of tiny bubbles, which protect against scaling from the freezing and thawing cycle in cold climates, as well as providing protection from damage caused by rock salt. This concrete should be used on sidewalks and driveways in cold climates.

The concrete mixture should be dry enough to stick together without crumbling but should be a mushy consistency. The mixture should never be runny.

For concrete that doesn’t demand water tightness and abrasion resistance, such as footings, foundation wails or retaining walls, the ratio of your dry mix should be 1 part cement to 3 parts sand and 4 parts gravel.

For a more critical concrete, use 1 part cement to 2 parts sand and 3 parts gravel.

To mix your ingredients, use a bucket as a measure. Fill the bucket with sand and level with a flat piece of wood. Dump the contents of the bucket onto a concrete slab or into a wheelbarrow, then fill, level and dump another bucket of sand. Fill and level a bucket of cement and add to the sand. Mix the two ingredients together then add three buckets of gravel and mix again. Make a depression in the center of your mixture and add water from a garden hose a little at a time, mixing the ingredients as you go. If you’ve added too much water, add more of the dry mixture in the same proportions as you originally mixed. Never add just cement, or sand or gravel. The proportions must be maintained in the concrete mixture.

To determine the amount of concrete you’ll need to mix, measure the length and width of the area you plan to concrete and determine the thickness of the concrete. Measurements should be in feet, with the thickness measurement expressed in fractions of a foot. Multiply the numbers and divide by 27, which is the number of cubic feet in a cubic yard, and you have a figure that represents the number of cubic yards of concrete you’ll need. For example, if the length of your area is 3ft, the width 4ft and the thickness of the concrete 3in (1/4ft), then multiply 3 x 4 x 1/4 and divide by 27. This gives you 12 cubic yards.

Building forms

Although building forms is an essential and exacting step in the pouring of concrete, it is also one of the most frustrating.

The form you use to brace the cement for the pour must be accurately constructed It must be level, plumb ana square. Your finished concrete will only be as accurate as your form. The form must also be braced solidly or it may collapse in mid-pour, creating a messy clean-up job and a waste of concrete.

But the frustrating part about the forms is that they’re only temporary. You must take the time to create some exacting carpentry and structural components, then, once the concrete sets, the forms must be dismantled.

Forms require different strengths depending on the project. A concrete footing, for example, can be poured into laminated fibre forms, while a foundation wall requires an elaborate structure.

We’ll deal with form construction for driveways, sidewalks and steps here.

For all the above concrete projects you’ll need a firm, compacted base. If your soil meets these requirements, simply remove grass and weeds and level the area. If not, you’ll need to excavate an area 10 to 15cm

(4 to 6in) deep to fill with gravel. Compact the gravel thoroughly.

For driveways, your forms should be made from 2×6 boards. Concrete should be 15cm (6in) thick for heavy loads, 10cm (4in) thick for cars. Support your forms with 2×4 stakes about 30cm (12in) long. Drive the stakes into the ground every 60cm (2ft) along the form. Use duplex nails to fix the forms to the stakes. Drive the nail through the stake into the form. Use double stakes wherever 2 x 6s butt.

Sidewalk forms are constructed in the same way as forms for driveways, except 2 x 4 wood is used for the boards rather than 2 x 6 because the sidewalk concrete only needs to be 10cm (4in) thick. Forms for sidewalks, paths and patios can be made from redwood or treated wood and left in place permanently for a decorative effect.

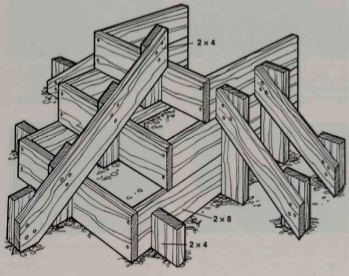

To pour a porch and steps combination, you’ll need some substantial forms well braced to prevent bulging. Step risers should be no more than 20cm (8in) high, while treads are 23 to 27cm (9 to 11 in) wide. Any larger and the steps would be difficult to negotiate. Use 2 x 8s for the frame. The actual width of the 2 x 8 is 7 1/2 in, which will make an adequate riser height. Brace the form with 2 x 4s and anchor the form to the foundation wall with metal anchors.

PORCH BUILDING FORM

To make a concrete porch, place footings 15cm (6in) below the frost line then build a strong form, anchoring it to the wall with metal anchors. You’ll need to apply an isolation joint between the foundation wall and your new porch. Slope the treads 6cm (1/4in) forward for runoff. Make sure you broom your concrete for a non-skid surface.

Make sure all forms are well oiled, to allow for easy removal.

Laying concrete

Outline your area with stakes and string, then begin your excavation. Dig deep enough to allow for a 10 to 15cm (4 to 6in) compacted gravel fill plus the thickness of your concrete. Allow for a pitch of 6mm (1/4in) per 30cm (12in) for drainage. A sidewalk or driveway should also be raised about 5cm (2in) above the surrounding land to allow for drainage.

Build your forms, making sure they’re level and well braced. Dampen the compacted gravel and then lay a wire-mesh reinforcement. Although the mesh isn’t essential for driveways or sidewalks, it does spread the stresses throughout the concrete when the ground heaves during the winter months, helping to prevent cracking.

Pour your concrete into the form. Try to place the concrete as close as possible to its final location. Excessive movement of the damp concrete can lead to scaling and dusting later.

Rake the concrete to the level of the forms, then, as soon as possible, strike off the concrete to level it. Use a flat 2 x 4 to strike off by resting the board on the forms and moving it back and forth as you advance.

Immediately after striking off, use a bull float — a short board on a long handle — to bring the surface level.

Immediately after using the bull float, run a trowel between the concrete and the forms. This helps free the forms later. The next steps must wait until the concrete has begun to set. There should be no water sheen on the surface and the concrete should be slightly stiff.

Run an edging tool around the edges to round them off, then use the jointing tool to cut the control joints. Control joints help eliminate cracking and should be cut across the width of driveways at 3m (10ft) intervals and up the middle of a double-car driveway.

On sidewalks, the control joints should be cut every 1.2m (4ft).

Use a wood float next to flatten and smooth the surface. This step will produce a slight texture in the concrete that is suitable for driveways and sidewalks.

If you need a very smooth surface, you’ll have to take the final step of steel trowelling. You may need to trowel two or three times for a smooth surface. The trowel is arched back and forth across the concrete, with the leading edge of the trowel slightly raised above the surface.

For the concrete to be durable, it must be cured over a period of days. Cover the concrete with plastic sheeting to keep the moisture in, and leave the sheeting in place, anchoring it with stones, for a period of 5 to 7 days.

Texturing concrete

The above method of pouring concrete offers a utilitarian cement slab. If you want to cast your own slab to make stepping stones or if you want to create a decorative garden path or patio, there are several texturing

effects that can be done to concrete to create a more attractive finish.

A basic texture that creates a non-skid surface especially suitable on pool decks is handled by a stiff-bristled broom. After steel trowelling, run the broom through the concrete to create wavy lines. The broom can be dragged lightly to produce a soft finish or heavily to produce a richer texture that also helps eliminate glare off the concrete.

You can produce swirled effects at the trowelling stage by holding the steel trowel flat against the concrete and making small or large swirling motions with your hand.

A wonderful texture can be created in the concrete by exposing the aggregate on the surface. When you trowel the cement you’re smoothing the cement paste over the top. If you remove that cement, you expose the aggregate, creating a rough stone surface. When mixing your concrete, try to use aggregate that is rounded rather than sharp edged. Pour the concrete in the same manner and trowel smooth. Then, with a garden hose and a stiff broom, spray the concrete with water to wash away the cement. The broom will help move the cement, exposing the rocks underneath. Use a gentle spray on the hose and only expose the top surface of the stones.

Pebble concrete produces a similar effect to the exposed aggregate concrete, but the pebbles are added after the pour, the stones are smoother and a variety of colors can be inserted into the concrete.

After pouring and striking off your concrete, place pebbles over the entire surface of your pour. Use the strike-off board to press the pebbles firmly into the concrete surface. Use a wood float to force pebbles lower into the surface and to smooth the cement over the stones.

Once the concrete has begun to set, you can start exposing the pebbles. To test the concrete, hose a gentle spray of water in one spot on the concrete and use a stiff brush to scrub the area clean. If this work doesn’t dislodge or overexpose the pebbles, the concrete is ready to work. Use the same treatment over the entire concrete, exposing as many of the pebbles as you can while still maintaining a smooth surface.

Coloring concrete

Although textured surfaces help detract from the plain dull gray color of concrete, you still have that flat color. If your plans call for something a little more daring, you can change the look of your concrete by adding colored pigment prepared especially for use in concrete.

If white is your choice of color, you can buy white Portland cement to use in your mixture. However, this cement is considerably more expensive than the regular Portland. And white concrete will show every stain, as well as help create a blinding glare on the concrete surface.

The white cement can be used with colored pigments, however, to give you cleaner, brighter, concrete colors.

There are three ways to color concrete. You can add pigments when you mix the concrete ingredients. This will mean a thorough mixing of the ingredients so that the color will be evenly blended. You can trowel the color in during the finishing stages. Or, after the concrete has set, you can use concrete paint or stain to provide the color you want.

You can never really predict the final color of concrete, but, as a rule, if you want a strong color, add about 3kg (7lb) of pigment to each bag of cement; if you like pastel colors, use 1 kg (2lb) of pigment for each bag of cement.

When adding color directly to the mix, you can eliminate great quantities of pigment if you use a two-step method. Lay a level of ordinary concrete to about an inch below the top of the form. Once the surface water has disappeared, complete the pour with a layer of colored concrete mixed without the coarse aggregate. The finishing techniques are the same as for ordinary concrete.

A second method of applying color is to trowel it in during the finishing. Pour your concrete as usual and level it with the strike-off board and bull float. Shake the dry mineral-oxide pigments over the surface of the concrete as evenly as possible. Allow it to rest for a few minutes to soak up some moisture, then trowel it into the surface thoroughly. Repeat if necessary, then follow up with the steel trowelling.

Staining and painting concrete is handled in the same way you would stain or paint any other surface. Make sure you buy stain or paint specially formulated for concrete.

USING CONCRETE step-by-step guide

1 You can buy ready mixed concrete where all you need to do is add the water or you can mix your own ingredients. This is an example of an undersanded mixture.

2 This properly sanded mixture has the right proportions of sand (fine aggregates), gravel (coarse aggregates) and Portland cement.

3 Portland cement, fine aggregate (sand) and coarse aggregate (gravel from1/4 to 1 1/2 thick) am used in varying proportions to make concrete.

4 After pouring the concrete, rake it to the level of the forms then strike off using a flat 2×4 Rest the board on the forms and move it back and forth.

5 Use a plank as a guide when cutting control joints. Control joints are placed where stresses accumulate to control cracks. Space control joints 10 to 20 ft. apart.

6 A series of floats and trowels are used to smooth the concrete surface both while the surface is wet and after the water sheen has disappeared.

7 Concrete must be cured for five to seven days for it to be durable. Cover the concrete with plastic to keep moisture in.

8 For a decorative effect in concrete, expose the aggregate on the surface. After trowelling smooth, use a hose and broom to wash away the surface cement.

9 To create a non-skid surface in the concrete, run a stiff broom through the concrete after steel trowelling to create wavy lines.